Research and Development

Our engineering team is working with new technology & delivering most effective

tech solution for our client through the continues Research & development. With the

in-depth study & research.

FUNDAMENTALS OF PACKAGING WITH ULTRASONIC WELDING TECNOLOGY

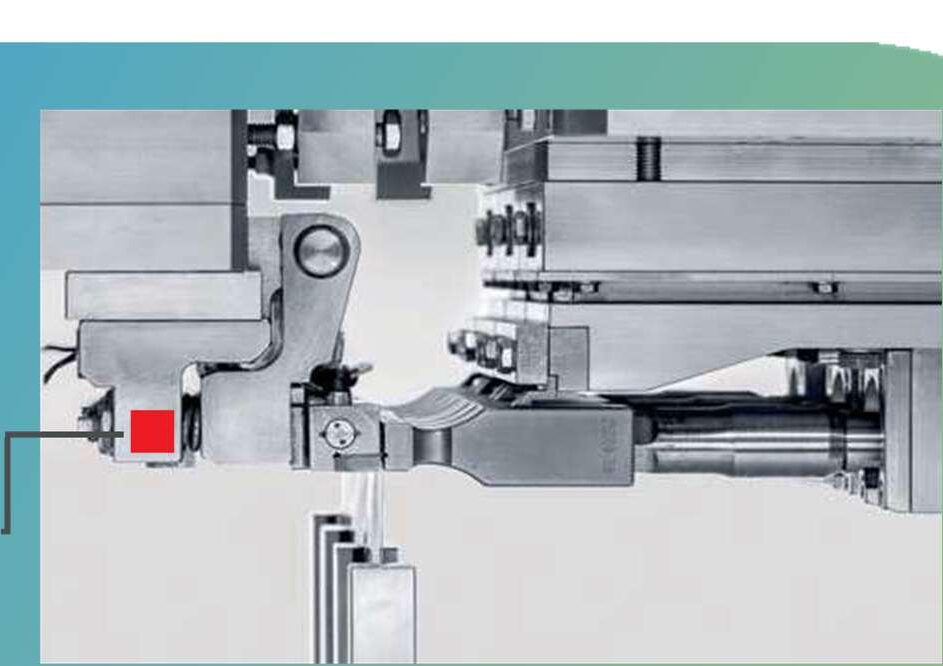

Ultrasonic Heat-Seal

Sealing packages with ultrasonics utilizes a

vibrating tool rather than hot sealing bars.

The advantage: The ultrasonic vibration

forces product contamination out of the

sealing zone. In addition, the ultrasonic

generator can identify bags with

irregularities such as folds in the seal area.

For most filling operations, products that

are powdery, liquid or lumpy make it

virtually impossible to avoid contaminating

the seal area with product. When sealing

with a traditional heat-sealing system, this

contamination could result in leakers in

which either the seal fails in the autoclave

or micro channels appear in the seal area.

Bacteria or mold can then penetrate.

Sealing with ultrasonics creates reliable

seals even in the presence of

contamination in the seal area. The

ultrasonic vibrations force the product out

of the sealing zone while the thermal energy

required for the sealing process is

produced by molecular and boundary

surface friction at the interface of produces

a high-strength hermetic seal between the

polymer layers. When using an

Ultrasonics sealing solution, the number of

leaking packages transported to the

autoclave process can be reduced to

almost zero.

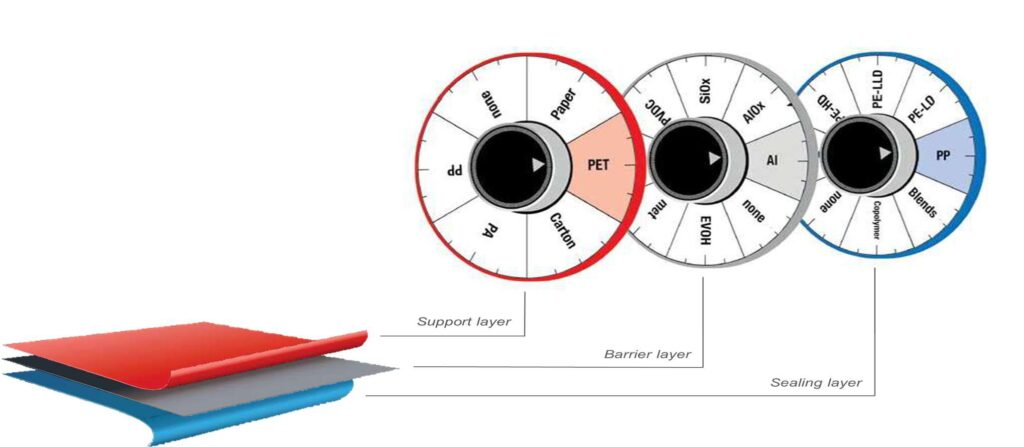

Structure Design Advantages

Ultrasonic sealing exhibits a high level of energy efficiency because energy is only needed during the actual

sealing process and power is only briefly delivered with typical cycle times being between 80 and 200ms.

Unlike traditional heat seal systems, ultrasonic systems are ready for use as soon as the ultrasonic

generator is switched on. Setup and changeover times are optimized because the typical temperature ramp

up and cooling cycles do not apply. A number of different parameters sets for each product type can be

stored as programs in the ultrasonic generator’s memory. Automatic recipe “on the fly” switch-over is

therefore possible and takes effect the next time the sealing process is initiated – no machine downtime or

cycle stop is necessary.

Ultrasonic sealing systems require a higher initial capital investment compared to heat sealing systems.

The key to a short ROI when investing in ultrasonics is the overall reduction in the number of seal leakers,

which will result in increased product throughput and decreased

PLASTICS FOR PACKAGING MATERIALS & SELECTION